The Alberti C-Clamp

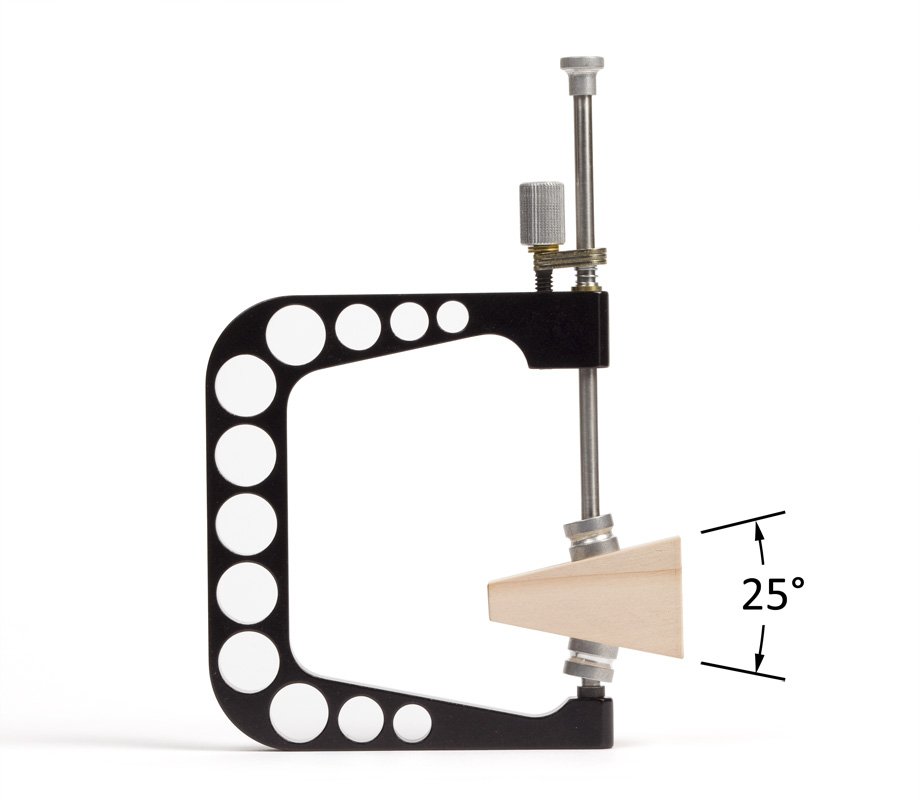

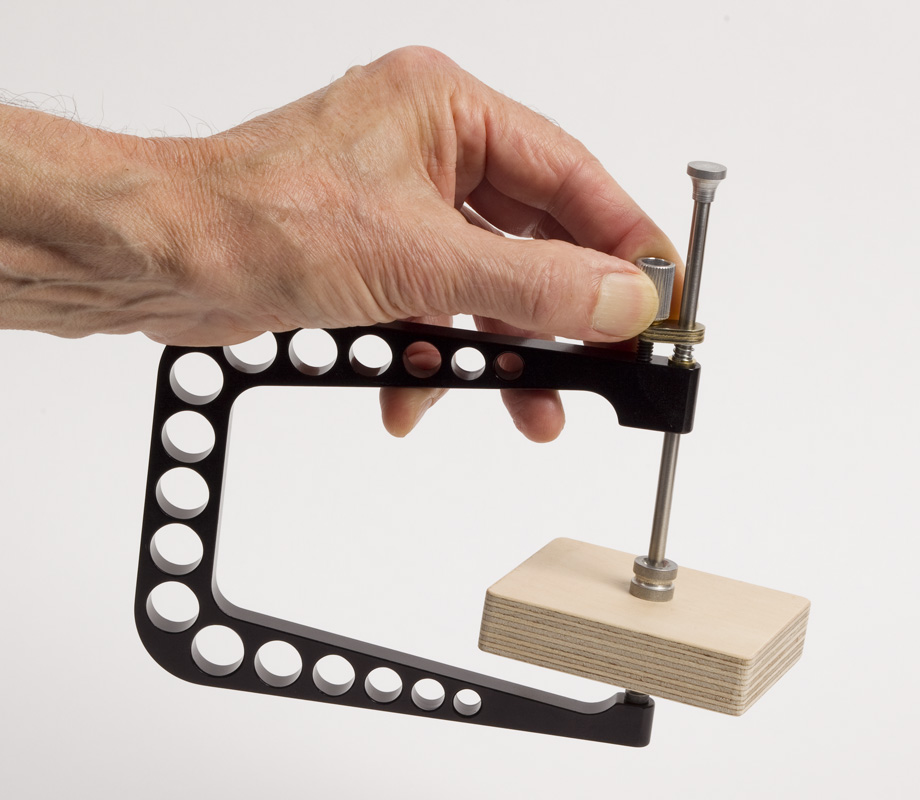

This c-clamp was designed for the assembly and restoration of musical instruments but has wide application anywhere a lightweight, precision, quick-setting (and releasing) clamp is of use.

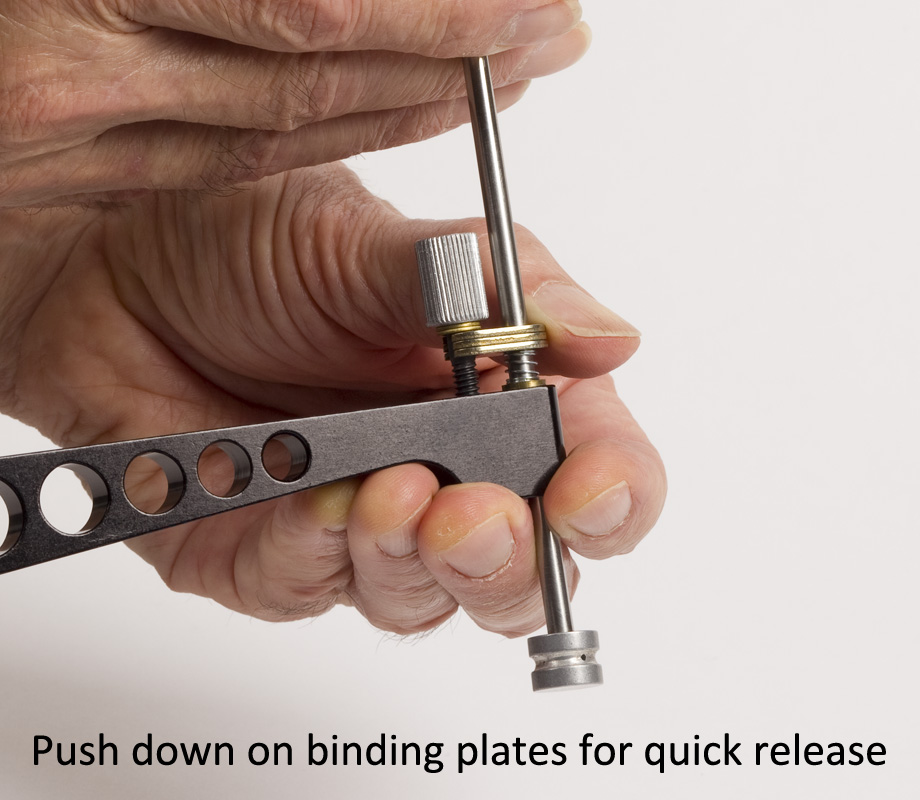

The clamp slide runs through binding plates which are, in turn, depressed by a knurled pressure screw. Clamping can be accomplished with one handed operation by pushing the slide down through the binding plates with your thumb until the clamp is held to the work and then additional force is applied with the pressure screw.

The clamp can be set with thumb pressure alone or tightened to 50 pounds of force if necessary. Loosening the pressure screw and releasing the binding plates allows the slide to be fully retracted in seconds.

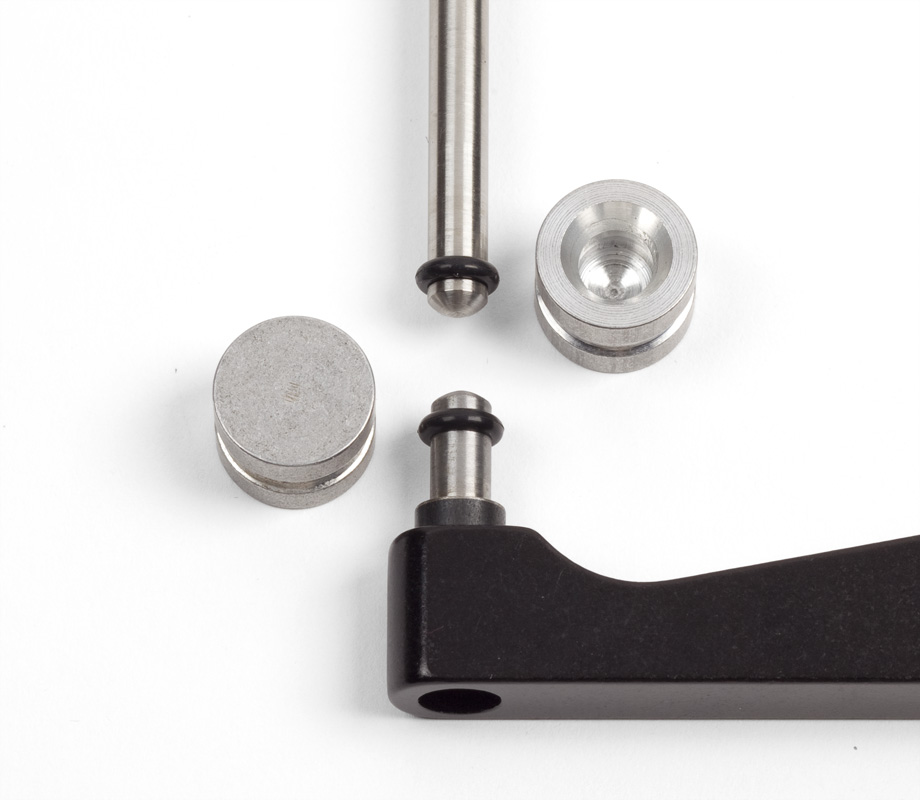

CNC machined from 2024 T4 aluminum with a stainless steel slide running in a brass bushing and removable anodized aluminum swivel pads, all parts of the clamp can be replaced or serviced. The swivel pads are mounted with friction retainers so they hold their position and can be separated from the clamp should you glue them to your work.

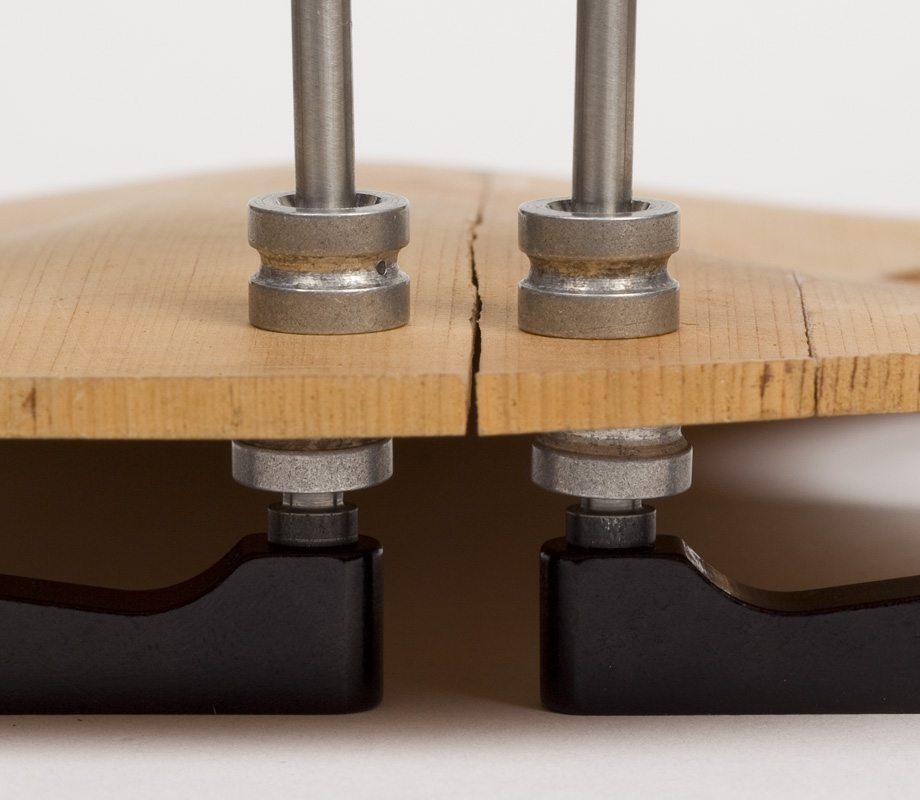

The pressure screws have an internal hex socket so the clamps can be nested next to each other and tightened with a key.

- Maximum Opening: 2-1/4″

- Throat Depths: 3″, 5″, 7″, 9″

- Pad Diameter: 1/2″

- Frame Width: 3/8″

- Weight: 3″ (120g, 4.25oz.), 5″ (150g, 5.25oz.), 7″ (176g, 6.20oz.), 9″ (230g, 8.00oz.)

- Max Force: Approximately 50 lbs.

- Frame Material: Anodized 2024 T4 Aluminum

- Clamp Shaft: Stainless Steel

- 3″ Clamp – $46

- 5″ Clamp – $52

- 7″ Clamp – $60

- 9″ Clamp – $68

To Order Call 800-982-4464

Please note the following:

For proper operation, the spring should always be in some compression from the binding plates so do not back the tightening screw out far enough to let the spring go loose.

To release the gold binding plates, push the outer ends toward the clamp frame.

If clamp is in use and under screw tension, you must slightly loosen the tightening screw before releasing the binding plates.

If you should glue a clamp pad to your work, just pop it off of the clamp. (Try snapping them off and on to see how they attach.)

The pad swivel mount on the sliding shaft is held on with cyanoacrylate (Crazy Glue, Zap, etc.) and if you ever need to remove the sliding shaft just remove the pad and “o” ring, heat the swivel mount with a flame until the glue fails. Re-glue with a drop of cyanoacrylate.

If clamps are nested next to each other they can be tightened and loosened with an Allen key. If, however, you overtighten them with an Allen wrench you will be preforming step 5 in order to straighten or replace the binding plates.

Recent Comments